Know Your Grade Limits to Avoid MEWP Downtime

by Sean Larin - Product Manager On Dec 20, 2018, 03:00 AM

Subscribe To Aerial Pros

Filter by tags

For mobile elevating working platforms (MEWPs), ground slope is a major contributor to machine stability and, ultimately, the operator’s safety. Among the list of mandatory equipment changes coming from the pending ANSI A92 and CSA B354 standards is the requirement for boom lifts to stop functions when the machine’s chassis angle exceeds its approved rating and the operator is at height. This may occur when a boom lift is being used on a slight hill, or when two of the four wheels are on an elevated surface such as a raised sidewalk. Operators will need to understand the equipment needs of each specific application, as certain jobs may require ground cribbing to be used or even a larger boom lift with a longer outreach from chassis to platform.

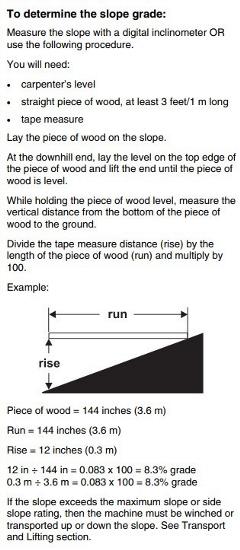

All MEWPs have a specific chassis angle limit when elevated, which is specified in the Operator’s Manual for the individual machine. Chassis slope can be affected by both the angle of the surface under the boom but also by obstacles above the ground that the tires are on top of, such as raised sidewalks, jobsite ramps and uneven gravel. In order to accurately measure chassis angle, an inclinometer or a manual slope calculation and conversion is needed.

All MEWPs have a specific chassis angle limit when elevated, which is specified in the Operator’s Manual for the individual machine. Chassis slope can be affected by both the angle of the surface under the boom but also by obstacles above the ground that the tires are on top of, such as raised sidewalks, jobsite ramps and uneven gravel. In order to accurately measure chassis angle, an inclinometer or a manual slope calculation and conversion is needed.Trained operators shouldn't confuse chassis angle limits while elevated with the similar sounding “gradeability,” which often refers to the ability to drive a stowed, self-propelled MEWP up slopes or over unimproved terrain while stowed and going in a specific drive direction. Incorrectly interpreting this as the grade limit a machine can elevate from could result in renting the wrong machine for a specific application or task.

Boom lift operators should be familiar with the Level/Tilt Alarms — the MEWPs’ slope limit systems that have been common in the industry for years. These are audible warnings and flashing beacons that are automatically activated by a sensor when the machine is tilted beyond its tolerances. These systems, however, have not traditionally disabled machine use or function. When the alarm sounded and/or flashed, the operator was made aware of the limits so that they could immediately lower the boom and repositions to a firm, level surface.

Under the new standards, all manufacturers’ boom lifts will have function cutouts at slope limits, only allowing for movement of the machine away from the limits. Rental store personnel can help their customers prevent unplanned downtime by working together to select a boom lift with sufficient outreach and height to get the job done, without the need to position on a slope exceeding the machine’s specific chassis angle limit.

Under the new standards, all manufacturers’ boom lifts will have function cutouts at slope limits, only allowing for movement of the machine away from the limits. Rental store personnel can help their customers prevent unplanned downtime by working together to select a boom lift with sufficient outreach and height to get the job done, without the need to position on a slope exceeding the machine’s specific chassis angle limit.Approved cribbing may also be used to provide a level surface for safe boom operation when surface angles are too great. When used as instructed, site constructed cribbing may bring a workplace surface to within the acceptable limits for MEWP operation as described in the Operator's Manual, helping compete jobs or tasks even in the most extreme jobsite environments.

Related Posts

Genie Safety Minute: Material Lift Load Center

Genie Safety Minute is intended to facilitate health and safety discussions on the job site.

Continue Reading

Genie Safety Minute: Safety On Slopes

Genie Safety Minute: Safety On Slopes

Continue Reading

Genie Safety Minute: Machine Bulletin Lookup

Genie safety minute is intended to facilitate health and safety discussions on the job.

Continue Reading