Rising Above the Challenges

by Genie On Apr 30, 2020, 03:00 AM

Subscribe To Aerial Pros

Filter by tags

McGough relies on experienced crew, Genie® lift equipment to pull through weather challenges

Constructing the new 420,000 ft2 Terex Utilities facility in Watertown, S.D., was supposed to be a straight-forward, uneventful construction process for McGough Construction of Fargo, N.D. Then again, nothing about working through harsh South Dakota winters is ordinary.

“The building is 30- to 40-ft high throughout most of the structure, which is typical industrial construction,” says Spencer Hilde, P.E., project manager for McGough, “but there is the high-bay area where the roof reaches 80 ft high.”

While it’s a typical build for McGough and the 25 subcontractors working on the project, the weather was doing all it could to throw the trades off schedule. “Thankfully, we built days into the work schedule for weather delays, because we needed all of them during the first winter of 2018-2019 alone,” Hilde says.

An extreme example: “We planned on paving the 10.5-acre asphalt parking lot in October 2018, but due to the wet weather, we had to stabilize the soil with Portland cement and pave it in September of 2019,” mentions Lexie Grandalen, project engineer for McGough.

The contract extends from August 2018 through July 2020. The new manufacturing facility will consolidate 10 company facilities spread throughout Watertown into one location to significantly upgrade efficiency. The manufacturer will build its aerial devices, auger drills and digger derricks at the new facility. Fiberglass boom testing necessitates the 80-foot-tall high-bay to allow the booms to be raised inside the building.

Framing at 50° below

Shakopee, Minnesota’s, Danny’s Construction Company of Shakopee, Minn., was among the first subcontractors on site to frame out the structure’s nearly seven miles of wide flange beam and column members. Framework began in late summer and lasted through winter, wrapping up in early summer.

Shakopee, Minnesota’s, Danny’s Construction Company of Shakopee, Minn., was among the first subcontractors on site to frame out the structure’s nearly seven miles of wide flange beam and column members. Framework began in late summer and lasted through winter, wrapping up in early summer.

Genie® GTH™-1056 and GTH-1544 telehandlers offering 10,000- and 15,000-lb maximum lift capacities respectively were among the first pieces of equipment at the jobsite to assist Danny Construction’s crew with the steel. More than a dozen Genie telehandlers, with capacities ranging from 5,500 to 15,000 lb, were onsite throughout the building schedule. Grandalen adds, “Telehandlers are the first pieces of equipment on the job and the last to leave.”

From moving material to unloading trailers, the telehandlers were tasked with a variety of duties. With the above-average precipitation being the worst in more than two decades, the Genie material handlers, with their powerful four-wheel drive and rough terrain tires, were, at times, called on to pull stuck equipment out of the mud. “They didn’t stall once,” comments Jeremy Maresch, iron worker superintendent for Danny’s Construction.

Danny’s Construction’s crew needed the machines to move more than 2,000 tons of structural material to frame the building. “The beams weighed up to 10,000 lb each, and there was a lot of heavy lifting completed by the forklifts (telehandlers),” adds Maresch.

The steel crew worked in some of the harshest winter weather conditions. Snow started falling in October and didn’t let up until April; wind chills registered -56 degrees Fahrenheit at one point during the long, cold winter. “We were still working when wind chills registered 30 below. We only took three days off in February due to the weather, and we hit all our milestones,” says Maresch.

Working right alongside the crew — day-in and day-out throughout the cold winter — were the telehandlers and Genie S®-60 and S-85 telescopic booms, along with multiple Genie rough terrain scissor lifts. Working in these extreme weather conditions, safety and machine uptime are paramount for keeping the project on schedule.

“You are always working around people, so safety is our number one priority,” comments Maresch. “The cab on the Genie forklift offers excellent operator visibility above and to the sides for lifting and placing materials. These extreme cold temperatures often results in hydraulic pump issues with equipment, but we experienced no problems with the forklifts.”

Controlling the controllable

With the weather working against them, McGough’s project leaders echoed Maresch’s comments on machine reliability. In addition, they emphasized having the right equipment on site when it’s needed as equally important to maintaining a schedule.

Major metropolitan areas with multiple national and local rental outlets give contractors plenty of options for equipment. However, this project is in rural South Dakota with a Watertown population just north of 20,000. No national rental chains have a physical location in the city, only a handful of local and regional stores. So, planning for equipment needs well in advance was a priority for McGough.

One such local rental outlet with a Watertown branch is Stan Houston Equipment Company, Inc., of Sioux Falls, S.D. For more than 70 years, the company has covered a large, sparsely populated geographical territory that includes South Dakota. Of its five locations, the headquarters is in the most populous area at 183,200 people, so its fleet doesn’t measure in the tens-of-thousands like some national rental outlets.

Stan Houston leadership knew it would take more than 50 pieces of Genie lift equipment to keep the trades working at the Watertown construction project, which is more than its Watertown inventory could absorb and still take care of existing customers. “Coordination is key and critical to the success of fulfilling the equipment needs for a large-scale project in a small town,” explains Larry Calmus, outside salesman for Stan Houston.

McGough worked with Stan Houston and some national rental chains with nearby outlets well in advance of the project’s start to ensure that the required equipment would be available throughout the two-year contract. Stan Houston pulled surplus equipment from its Sioux Falls and Aberdeen, S.D. branches, as well as its Sioux City, IA, location to prepare for the increased demand in Watertown.

New Genie lift equipment was also added to Stan Houston’s fleet for the project. “We are a progressive company and will buy what’s needed to fill customer need,” adds Calmus.

Working with its rental partners, McGough moved into the height of construction activity in early fall 2019, confident it would have the scissor and boom lifts and telehandlers it needed to stay on schedule.

Full steam ahead

The facility’s blueprints call for 1,800 light fixtures, 225,000 ft of conduit/cable and more than 250 miles of wire. Scissor lifts and telescopic booms were needed to run utilities at ceiling height throughout the building and high-bay area. “We used BIM (Building Information Modeling) to detect and resolve conflicts with the utilities and to make sure the cranes could fit through the doorways,” says Hilde.

The facility’s blueprints call for 1,800 light fixtures, 225,000 ft of conduit/cable and more than 250 miles of wire. Scissor lifts and telescopic booms were needed to run utilities at ceiling height throughout the building and high-bay area. “We used BIM (Building Information Modeling) to detect and resolve conflicts with the utilities and to make sure the cranes could fit through the doorways,” says Hilde.

Genie recently started a BIM library of some of its most popular models, including the Genie S-65 XC telescopic boom and Genie GS™-4047 scissor lift. This helps to resolve conflicts with equipment fitting into spaces inside the building to complete construction. “There were certain areas where we had to remove the rails on the Genie GS-4047 scissor lift to fit under the doorways in some of the office areas,” comments Eric Moore, facilities manager for Terex Utilities.

With so many miles of wire to run, hundreds of lights to hang and ductwork to install in the ceiling, subcontractors like Minneapolis’s PEC Solutions are looking for lift capacity in addition to reliability to boost efficiency. The company has 16 Genie GS-4047 scissor lifts at the site to complete their part of the project.

“Genie’s lift capacity is 150-lb heavier than competitive models,” offers Matt Swanson, field supervisor for PEC Solutions. “This reduces the number of times workers have to raise and lower the lift to get materials, which boosts efficiency.”

Genie Xtra Capacity™ (XC) telescopic booms, like the Genie S-85 XC machines working in the high-bay area at the Watertown project, offer dual lift capacity — 660-lb unrestricted and 1,000-lb restricted — to perform a wide range of heavier lift tasks. This gives contractors like PEC Solutions the ability to have up to three people work onboard, while still leaving room for tools and jobsite materials. Alternatively, says Swanson, “If I have a 200-lb person on the boom, this provides the ability to have more than 400 lb of equipment and wire on the platform and still have unrestricted boom movement.”

Even with historic precipitation and record cold temperatures working against them, McGough and its subcontractors are still on track to meet the July 2020 contract deadline. “Communication is critical in keeping on schedule, and we have Monday morning meetings with representatives of all the trades working that week to cover any issue that could cause a delay,” says Moore.

Open communication, flawless execution, skilled workers and reliable, efficient equipment will always win in a battle against Mother Nature.

Related Posts

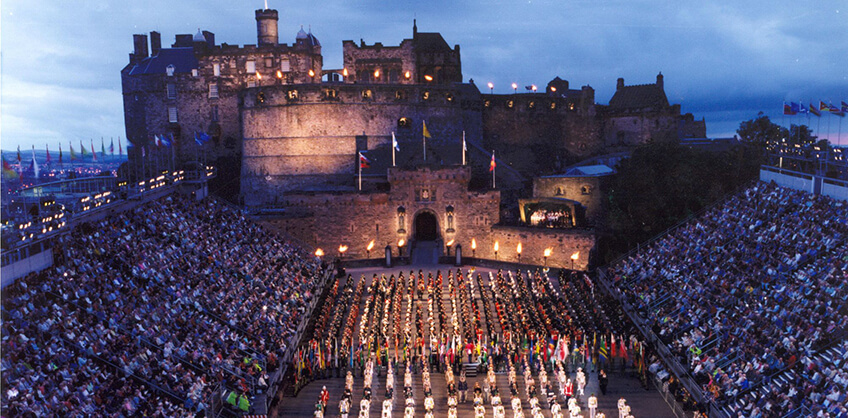

Stepping up on Safety in challenging Netting Application in Scotland

For scale, no show in Scotland can rival the Royal Edinburgh Military Tattoo.

Continue Reading

Green Access Solutions: Rising to Meet Today’s Environmental Challenges

Around the globe, capital cities and large provincial towns are going greener.

Continue Reading

Making Way for Genoa's New Morandi Bridge, Italy

Two Genie® SX™-180 boom lifts involved in a high-precision demolition process.

Continue Reading