Huge Expansion project at Kaz Minerals Copper Mine, Kazakhstan

by Genie On Aug 27, 2020, 03:00 AM

Subscribe To Aerial Pros

Filter by tags

As part of $1.2 billion (€1.08 billion) expansion project at its copper mine in Aktogay Kaz Minerals turned to Genie for a solution adapted to steel construction assembly work performed in conjunction with Terex® cranes. To support the project, Terex equipment providers Korund Group of Companies based in Oskemen, Kazakhstan, supplied a battalion of 18 Genie® machines among which 12 Genie Xtra Capacity™ (XC™) boom lifts. Models included six, 34-m (111-ft) Genie SX™-105 XC and six 40.10-m (131-ft) Genie SX-125 XC units.

An intensive, three-year mission performed in a challenging, remote environment.

Located in the east of Kazakhstan where the closest border meets with western China, the Kaz Minerals Aktogay copper mine is a large scale, open pit operation with a maximum annual ore processing capacity of 25 million tons. By 2021, when the site’s expansion is completed, capacity will reach 50 million tons, doubling its capacity for a mine life of 28 years.

In the meantime, work is underway on a big scale, from the installation of a new concentrator used to extract copper sulphide from raw ore, to new conveyors and other processing equipment. The site’s development also includes a link with the national rail network, access to roads to the Chinese border and office buildings and living quarters for the 1,500 people employed at the site.

Genie Xtra Capacity – a productivity must-have

Mr. Sergey Bereza, the owner of Korund, says: “When you have around 20 large models of the same brand working on a project like Aktogay, the challenges involved make it easy to gauge their performance. We are glad to say that, in the eight months that they have been in operation, our Genie XC booms have proved to be extremely robust and reliable, running virtually non-stop. On a job that involves working at height with heavy tools and materials, we can definitely say that increased lift capacity is big productivity benefit.”

Engineered to work more productively in heavy lifting access applications (construction, bridge inspection, maintenance on stadiums and sports arenas or industrial oil and gas, telecommunications and utilities facilities), Genie XC booms combine a 1.52-m (5-ft) robust articulating jib with a dual lift capacity of 300-kg (660-lb) unrestricted and 454-kg (1,000-lb) restricted — one-third more than the industry standard to provide the ability to get more work done using a single machine.

Genie SX-105 XC and SX-125 XC models also feature the unique Genie mini XChassis™ design that provides the benefits of a compact 3.94 m (12 ft 11 in) x 4.11 m (13 ft 6 in) footprint and an extendable/retractable axle system with a narrow profile for easier transport and simple-to-access, low-effort maintenance.

To increase performance, reduce set-up time and improve overall productivity, all Genie XC models boast zero-load field calibration thanks to a load sense cell that continuously checks the weight in the platform to make sure that the machine stays within the machine’s load limit.

“Three years may seem long enough, but on a project of such a massive scale in such a remote part of the world, time can be a real challenge,” adds Sergey Bereza. “With temperatures that range from −20 °C (−4.0 °F) in the winter and 30 °C (86 °F) in the summer, our harsh climate and performing intensive heavy work in rugged conditions can also have an adverse effect on machinery.”

Great technical support, despite the distance

He continues: “In terms of productivity, it is imperative to be able to rely on skilled support to ensure that equipment is maintained properly. And when we have needed specialised technical support, Gökhan Gültekin, Genie Sales and Technical Manager, Terex AWP, for Turkey and the Caspian Sea Region has been great, responding to our needs in a timely fashion – despite the five-hour flight and 11-hour train journey it takes to get here!”

|

|

| Gökhan Gültekin, Genie Technical Manager with Genie equipment in the snow in KAZ Minerals site | Tough operations at height demand Genie equipment to assist in steel assembly work |

Related Posts

The Right Boom Lift Option for Any Jobsite Need

Every jobsite has its unique challenges and requirements; there is a lot of variety in the type of work that end-users are doing.

Continue Reading

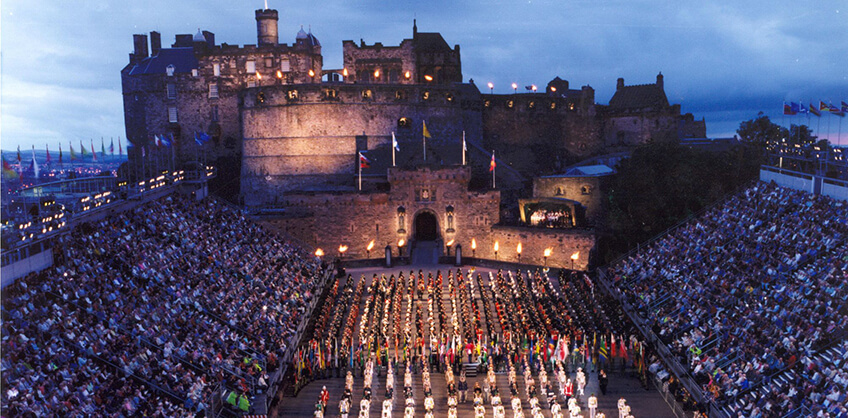

Stepping up on Safety in challenging Netting Application in Scotland

For scale, no show in Scotland can rival the Royal Edinburgh Military Tattoo.

Continue Reading

Recommending the Right MEWP

In today’s competitive market, we, at Genie, know that it is more important than ever for you to establish and earn your rental customers’ respect as a trusted advisor.

Continue Reading