Transporting Genie® Booms Equipped with Load Sense Systems

by Jason Berry - Product Safety ManagerSr. Product Safety Manager On Feb 18, 2021, 03:00 am

Subscribe To Aerial Pros

Filter by tags

Transporting a large piece of aerial equipment can be a challenge, and safety is the key ingredient. Ask any shipping or logistics expert, and you’ll hear stories of shipping feats they’ve accomplished. But, how does this apply to boom lifts that have load sense systems? What’s different? What steps must you take to fulfill safety and efficiency needs?

Read also on the Genie® Aerial Pros™ site: Preparing for Platform Load Sense

Before we outline the 3-step process to follow, there are prerequisites to note. Always refer to the model-specific Genie® Operator’s Manual for full transport instructions prior to transporting a boom. When possible, transport the boom with the platform floor horizontal to the transport trailer bed. Select booms and trailer combinations do not accommodate this orientation due to length, in which case you must follow the Operators Manual for positioning the securing platform.

Prior to transport, also make sure the boom has the current software installed. This is available at https://www.genielift.com/en/support/firmware.

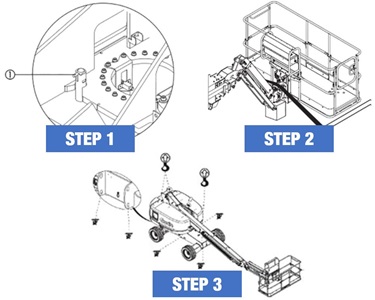

Now, onto the three steps:

Step 1: Securing to Truck or Trailer for Transit

- Always use the turntable rotation lock pin each time the machine is transported

- Turn the key switch to the off position, and remove the key before transporting

- Inspect the entire machine for loose or unsecured items

Step 2: Securing the Platform

- Make sure the jib and platform are in the stowed position

- Secure the platform with a nylon strap placed parallel to the strap guides. Do not use excessive downward force when securing the boom section

- Support the platform support, opposite the nylon strap, with a force absorbing chalk such as foam, rubber or wood

Step 3: Securing the Chassis

- Use chains of ample load capacity

- Use a minimum of six chains

- Adjust the rigging to prevent damage to the chains

- For a diagram, refer to the Lifting Instructions in the Operator’s Manual

But wait, there’s more: An additional notice from the Genie Safe Use Plan Guidance states:

When a mobile elevating work platform (MEWP) is loaded or unloaded from a transport vehicle on a public road, the users and operators must ensure that appropriate measures are taken to protect everyone in or near the area. These measures may include, but are not limited to:

- Warning cones or hazard tape

- Signs and signal personnel wearing reflective clothing

- Flag personnel to warn people and other vehicles of the vehicle’s presence.

This is only an overview. Additional information can be found in the ANSI A92.24-2018 and CSA B354.7:17 standards. We encourage you to purchase a copy of the standards and read them in their entirety prior to developing your Safe Use Plan. The ANSI A92.22-2018 Standards can be purchased at https://shop.saiaonline.org. The CSA B354.7:17 Standards can be purchased at https://store.csagroup.org.

Want to know more? Check out the Genie hub for A92 updates and more: www.genielift.com/A92.

Related Posts

Benefits of Preventive Maintenance for MEWP Rental Fleets

As is the case with all equipment, mobile elevating work platforms (MEWPs) require regular, preventive maintenance to maintain peak performance. Ensuring a MEWP gets the maintenance it needs is not only important to safety, but to performance as well.

Continue Reading

How Machine Data Influences MEWP Maintenance and Service

When looking at a machine’s service and repair from that perspective, downtime costs a rental business big time.

Continue Reading